Process Equipment

We Malik Polychem Private Limited are engaged in manufacturing of Reaction Vessel, Heat Exchnger, Blender Process Equipment, Nutsche Filter, Agitated Nutsche Filter, Pulverizer Sparkler Filter, zero hold Pressure Mixer, Powder and Liquid System, Vibro sifter

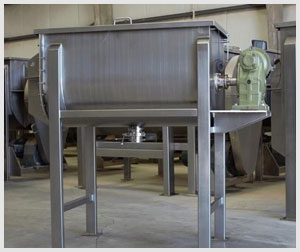

Blender

Ribbon Blender

Ribbon Blenders consist of a U-shaped horizontal trough and a specially fabricated ribbon agitator. A ribbon agitator consists of a set of inner and outer helical agitators. The outer ribbon moves materials in one direction and the inner ribbon moves the materials in the opposite direction. The ribbons rotate at approx. 300 fpm moves materials both radially and laterally to insure thorough blends in short cycle times. Ribbon agitators are used for blends that will be between 40 and 100% of the rated capacity of the blender.

An alternate agitator is our paddle design. The paddles are positioned to move materials in opposing lateral directions and radially. The paddle design is normally applied where friable materials are being blended and when batches as small as 15% of the total capacity are going to be mixed in one blender.

Octagonal Blender

The blender features an octagon shaped body with rectangular central portion and top & bottom polygonal frustum. These are provided with baffles for fast and efficient mixing, charging port and outlet with butterfly valve. In the octagonal blender, granules come in a uniform way from all the sides due to its octagonal shape; hence requirement of RPM is less. The Octagonal Blenders are ideally suited for Crystalline & Granular type of materials.

The blender features an octagon shaped body with rectangular central portion and top & bottom polygonal frustum. These are provided with baffles for fast and efficient mixing, charging port and outlet with butterfly valve. In the octagonal blender, granules come in a uniform way from all the sides due to its octagonal shape; hence requirement of RPM is less. The Octagonal Blenders are ideally suited for Crystalline & Granular type of materials.

Special Features:

- The entire unit is mounted on a sturdy stand, complete with electric motor and gear box

- It can be supplied with bin charging system and can be designed for vacuum, dust free charging & discharging of product (Optional)

- The machine is provided with control panel board and safety railing

- It is a slow speed blender and has a removable baffle mounted through a rectangular lid

- Simple design facilitates easy cleaning.

- The power consumption is comparatively lower than the other similar type of blenders.

Mass Mixer/ Paddle Mixer

Mass Mixer is a pharmaceutical machine, specially designed for thorough mixing of wet as well as dry or lump material. It is suitable for tablet granulation process. The equipment has paddle like blades for efficient granulation and mixing. It also consists of a leak proof seal tilting arrangement for convenient unloading of products. Engineered to precision, the machine provides with transparent polycarbonate dust cover with inter locking system to view the raw material being mixed.

Easy to operate, the range of our Mass Mixers is ideal for homogeneous mixing of particles in diverse industries including Food, Mineral, Pharmaceutical, Paint & Chemical Industries.